Bututun Karfe mai zafi

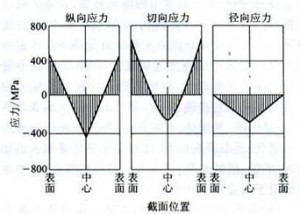

Maganin zafi yana nufin hanyar maganin zafi sau biyu na quenching da matsanancin zafin jiki.Manufarsa ita ce sanya workpiece su sami ingantattun kayan aikin injiniya.Babban zafin jiki mai zafi yana nufin zafi a 500-650 ℃.Yawancin sassa masu zafi suna aiki a ƙarƙashin aikin babban nauyi mai ƙarfi.Suna ɗauke da tasirin tashin hankali, matsawa, lankwasawa, tsagewa ko ƙarfi.Wasu saman kuma suna da gogayya, wanda ke buƙatar juriyar lalacewa.A taƙaice, sassan suna aiki ƙarƙashin matsalolin mahalli daban-daban.Irin wannan nau'in sassa na musamman na injuna da injuna daban-daban, kamar su igiya, igiyoyi masu haɗawa, studs, gears da sauransu, waɗanda ake amfani da su sosai a cikin kayan aikin injin, motoci, tarakta da sauran masana'antun masana'antu.Musamman ga manyan sassa a cikin masana'antun kayan aiki masu nauyi, ana amfani da maganin zafi sosai.Sabili da haka, maganin zafi yana taka muhimmiyar rawa wajen maganin zafi.A cikin samfuran injina, saboda yanayin damuwa daban-daban, aikin da ake buƙata ba iri ɗaya bane.Gabaɗaya magana, kowane nau'in sassa masu zafi ya kamata su sami ingantattun kaddarorin injiniyoyi, wato, haɗin da ya dace na babban ƙarfi da ƙarfi mai ƙarfi don tabbatar da aikin sassauƙa na dogon lokaci.

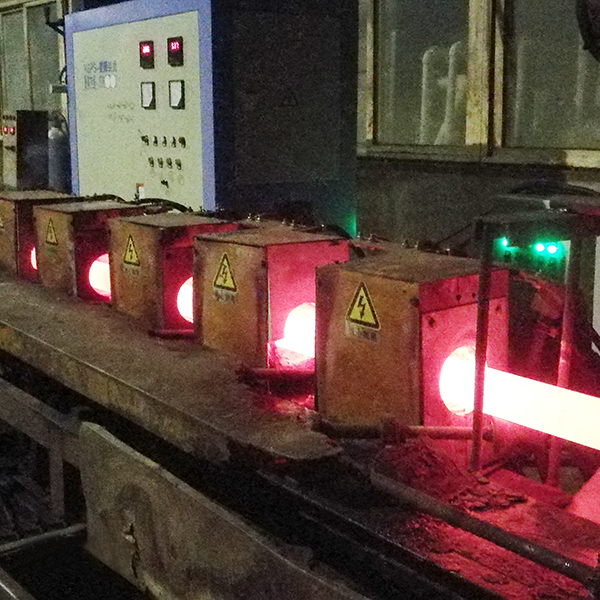

Maganin zafi na bututun ƙarfe yana ɗaya daga cikin mahimman matakai a cikin masana'antar injiniya.Idan aka kwatanta da sauran fasahar sarrafa, zafi magani gabaɗaya baya canza siffar da sinadaran abun da ke ciki na dukan workpiece, amma baiwa ko inganta yi na workpiece ta canza ciki microstructure ko sinadaran abun da ke ciki na workpiece surface.Siffar sa ita ce haɓaka ingancin ciki na kayan aiki, wanda gabaɗaya ba a gani ga ido tsirara.Don yin bututun ƙarfe yana da kayan aikin injiniya, jiki da sinadarai da ake buƙata, tsarin kula da zafi sau da yawa yakan zama dole ban da zaɓin madaidaicin kayan aiki da matakai daban-daban.Karfe shine kayan da aka fi amfani dashi a masana'antar injina.Microstructure na karfe yana da rikitarwa kuma ana iya sarrafa shi ta hanyar maganin zafi.Bugu da ƙari, kayan aikin injiniya, jiki da sinadarai na aluminum, jan karfe, magnesium, titanium da kayan haɗin su kuma za'a iya canza su ta hanyar maganin zafi don samun kayan aiki daban-daban.

Sunan samfur:Bututun ƙarfe mai zafi

Wurin Asalin:Shandong, China

Kewayon sarrafa abun ciki na carbon:0.30 ~ 0.50%.

Ƙarfe mai ƙarewa:ASTM 1045, ASTM 5140, ASTM 4140

Rabe-raben maganin zafi:

● Carbon quenched da tempered karfe

● Alloy quenched da tempered karfe

Daidaita taurin

● Tsakanin ƙasa

● Tsakanin saman

Domin samun kyakkyawan aikin gabaɗaya na ƙarfe mai zafi, ana sarrafa abun cikin carbon gabaɗaya a 0.30% -0.50%.

Ƙarfe mai ƙarewa:ASTM 1045, ASTM 5140, ASTM 4140

Nau'i: bututu da bare

Karfe maganin zafiGirma:

Diamita na waje:1/2" - 24"

Kaurin bango:Saukewa: SCH10-XXS

Tsawon:5.8-12 Mita

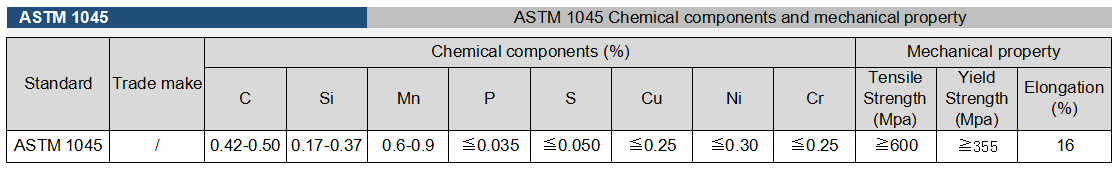

ASTM 1045 Abubuwan sinadaran da kayan aikin injiniya:

ASTM 1045 MAGANIN ZAFI:

Taurin karfe 1045 bayan quenching: HRC 56-59

Zazzabi mai zafi: 560 ~ 600 ℃.

Bukatun taurin zafin zafi: HRC 22-30

Manufar maganin zafi:M inji Properties.

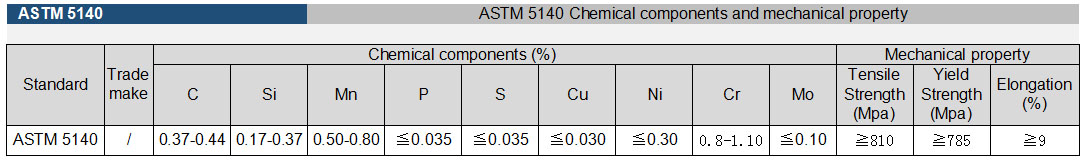

ASTM 5140 Abubuwan sinadaran da kayan aikin injiniya:

GANO:

APPLICATION:

Bayan quenching da tempering a matsakaita zafin jiki, ana amfani da shi don kera sassan da za su iya jure babban nauyi, tasiri da matsakaicin gudu, kamar gears, manyan shafts, rotors famfo mai, sliders, collars, da dai sauransu.

ASTM 5140 GEARS

ASTM 5140 GASKIYA